JAR, Ingeniería & Equipos Ltda posee la mas surtida gama de accesorios para la instalación y mantención de difusores.

Para mas información descargue el archivo adjunto.

JAR, Ingeniería & Equipos Ltda posee la mas surtida gama de accesorios para la instalación y mantención de difusores.

Para mas información descargue el archivo adjunto.

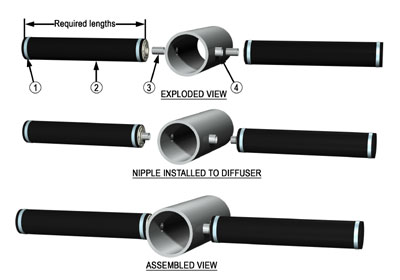

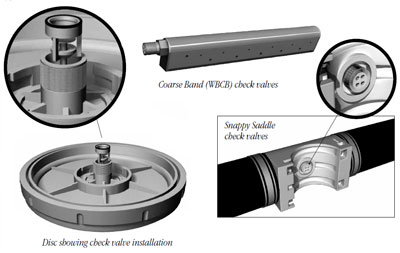

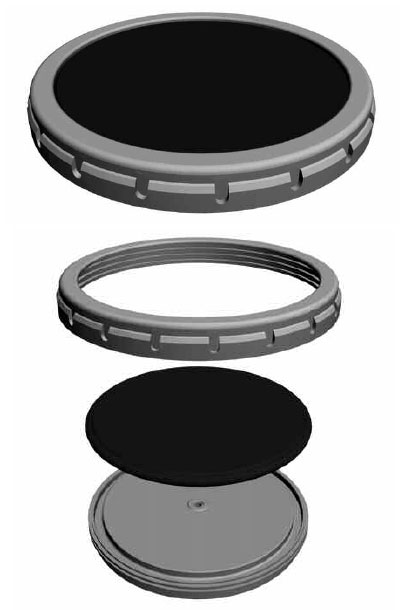

JAR, Ingeniería & Equipos Ltda posee la más completa línea de difusores, accesorios y repuestos para sistemas de aireación de la marca SSI™.

Entre los productos que nuestra empresa ofrece se encuentran diferentes tipos de discos y tubos difusores, además de una serie de otros productos que son detallados en el siguiente documento.