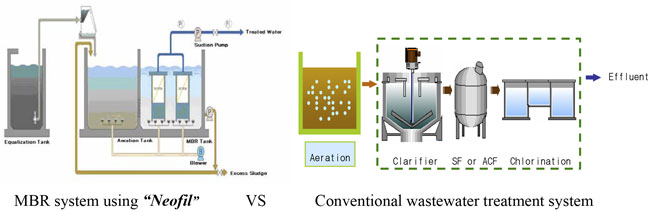

Membrane Biological Reactor(MBR) technologies successfully treat municipal, commercial, and industrial wastewater resulting in high-quality treated water for discharge and reuse applications these days. State of the art in “Neofil”(Submerged flat sheet membrane) is the only solution to meet the standard.

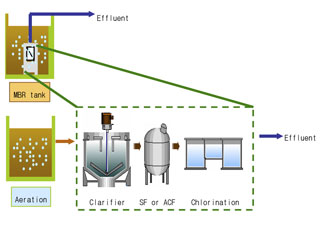

Compare with conventional wastewater treatment system VS MBR system using “Neofil”

Benefits of MBR system

- Excellent water quality

Complete separation with BOD, SS, produce to permeated water for reuse.

Removes suspended solids by filtration rather than settling, the process is much more effective than conventional treatments and can operate at much higher mixed liquor suspended solids (MLSS) concentrations.

- Small footprint

MBR is an activated sludge reactor system that utilizes a single complete mix reactor in which all the steps of the activated sludge process occur with a membrane filter system submerged in the reactor. Easy to modify existing facilities. It will save area and cost effectively.

- Simple process and Easy maintenance

Simply MBR system process will make easy maintenance, and reducing man power ,operating costs and energy savings.

MBR Applications

- Sewage wastewater treatment

- Municipal and commercial biological waste water

- Livestock wastewater

- Organic wastewater

- Sewage waste water treatment(300 m3/D) in Korea

- Waste water treatment of Drinking factory(700 m3/D) in Korea

- Sewage waste water treatment(1,000 m3/D) in Dubai

- Sewage waste water treatment(1,600 m3/D) in Australia

- Live stock waste water treatment in Japan

“Neofil” Specification

MBR UNIT is consist of two parts which is element block and aeration block. The element block has a number of membranes stacked together with equal distance and each flat sheet membranes attached on both side of spacer and this element is connected with tube to permeated water header to produce permeated water for reuse.

Why “Neofil” is the best for MBR system?

Our creative & advanced “Neofil” has the reasons……

- Consistent and Excellent effluent water quality

Using membrane to separate sludge and retain activated sludge at high Concentration to removing BOD, SS and fecal coliform, therefore treated water is suitable for beneficial reuse

- High Flux, Low fouling of membrane material

Using polyethersulfone(PES) material of membrane and it contains more hydrophilic property than other brand membrane to produce high quality of treated water. Also it has low contact angle and evenly distribute the pore sizes.

- Better design of membrane(flat sheet)

No sludge tangled on the surface because its flat and cleaning by upward water by air diffuser and no breaking and surface blocking near the ends of membrane because its flat sheet membrane.- Easy maintenance & Control

Maintain high MLSS to reduce activated sludge tank and it will not Depend on influent water quality to produce stable permeated water also sludge is separated by membrane to produce compact size of area and easy maintenance.